Chemical Power Loading and Conveying System

The Process Challenge

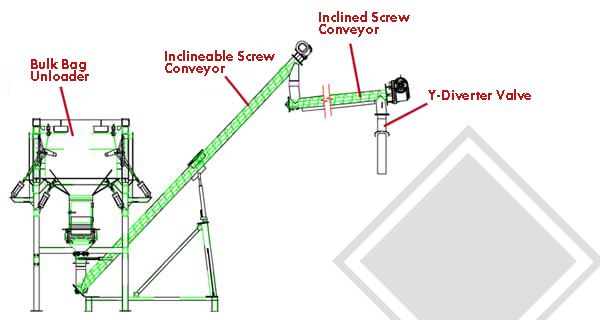

A company looking to expand its facility contacted S. Howes to design an unloading and conveying system to transport cuprous oxide and boric acid chemical powders.

The Solution

Since the unloading area was far from the processing area, the system was designed with two inclinable conveyors to transport the material. The chemical powder was loaded into a bulk bag unloader before it was discharged into an 18-foot inclined screw conveyor and then went into a 47-foot conveyor, which featured a two-way Y diverter valve where the powder was diverted into one of two bins depending on the batch of material.

Components

- Heavy-Duty Bulk Bag Unloader with Dust Collector

- Model 6C18 Inclined Screw Conveyor

- Model 6C47 Inclined Screw Conveyor

- 60-degree 2-Way Gravity Diverter Valve

- Consolidated Control Panel

Photos and drawings are not intended to show or suggest the use or non-use of any operator protection systems.

The Result

The system met the company’s conveying, expansion, and space needs and offered the flexibility to process different batches of materials.