Skip to content

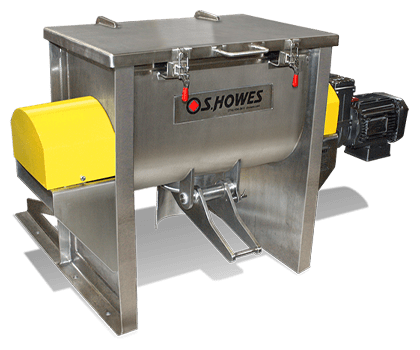

ES-100 Sanitary Blender

Standard Design Features

- Mixer tank inside dimensions of 12” wide x 20″ long

- Mixer is furnished with welded heads for leak-free operation, welds ground to 1/8” minimum radius, no crevice contamination

- 304 Stainless steel construction in product contact areas

- Mild steel construction in non-product contact areas

- S. Howes standard flanged double ribbon agitator

- Flanged journal design (with no exposed threads) for top removal of cylinder for ease of cleaning

- Center discharge with 4” manual plug valve

- Hinged & clamped flat cover

- Lift-out safety grating

- Magnetic limit switch mounted to safety grating, 120 VAC, not wired

- Food grade white neoprene strip gasket

Standard Components

- Drive Class I application, complete with shaft mounted direct drive gearmotor for a mixer speed of 92 RPM at 60 Hz

- 1 HP, TEFC, 1800 RPM, 3/60/230-460 TEFC inverter duty motor

- Spherical roller pillow block bearings for shaft support

- OSHA compliant bearing and shaft guards

Optional Components

- Rotating mechanical shaft seals

- Seals mounted to end plate and sealed with RTV

- The seal require 3 – 5 psig compressed air purge

- Two triple blade chopper style intenifiers

- Replaceable, interchangeable blades

- 1/2 HP, TEFC, 1800 RPM, 3/60/230-460 TEFC standard duty motor

- Portable carbon steel support stand

Finish Details

- Product contact surface finish, 2B (80 grit) finish

- Exterior surface finish, uniform scotch brite

- Interior welds to be continuous, no cracks or crevices, ground flush and polished to 80 grit finish

- Exterior welds to be continuous, no cracks or crevices, ground smooth & blended with scotch brite finish

- All exterior steel components to be painted with one primer coat and one top coat (food grade epoxy paint, white)

- All welding to be done as TIG welds

To rent a stock item call 716.934.2611 or fill out and submit the form below.