Tubular Filter

Single, dual or multiple tube separation of suspended solids.

S. Howes tubular, in-line pressure filters are used for the separation of suspended solids from a liquid stream. It is best used for easily filtered granular solids less than 500 PPM and where the differential pressure across the filter is less than 20 psi at 1/8 inch cake thickness max.

Tubular filters are comprised of an outer housing and a removable, reusable filter element. The filters provide the flexibility to accommodate a wide variety of needs and applications.

S. Howes offers tubular filters in single, dual, or multiple-tube configurations tailored to fit your space, piping, and processing requirements. Our Howes Filters come in stainless steel with 4″ and 6″ diameter tubes. The tubular filter media from Howes is reusable across various applications and built for durability.

S. Howes Tubular Filters are engineered for your application.

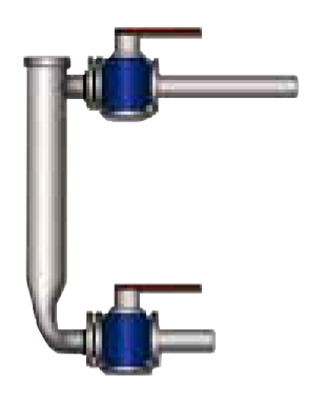

Single Tube Filters

The Howes Single Tube Filter is suitable for many industrial applications from straining to fine polish filtration. Single Tube Filters are available in sizes from 85 to 594 square inches for flow rates from under 1 to over 300 GPM. A wide selection of filter media is available to handle levels of separation from 3/16 inch to 1 micron.

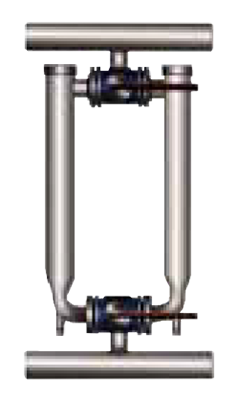

Dual Tube Filters

Howes Dual Tube Filter System allows for continuous flow. In the Dual Tube Filter arrangement, two filter units are interconnected with 3-way plug valves or inline full ported 3-way ball valves. One unit operates (on stream) while the other unit is on standby (off stream) for cleaning or inspection. The Howes Dual Tube Filter System typically has the same flow capacity as the Single Tube Filter but can be increased with optional valve arrangements.

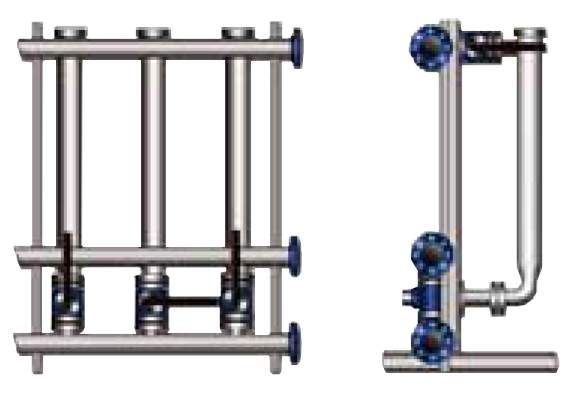

Multiple Tube Filters

The Multiple Tube Filter Systems manifold multiple filters together for parallel operation and offer up to 5,000 GPM flow capacities. The System can provide continuous, uninterrupted flow with automatic intermittent cleaning of the filter elements during backwashing. The systems are typically sized to maintain flow capacity while one unit is offstream for backwashing. Manifolding arrangements can be made to permit backwashing with either the process stream (internal) and/or another stream (external). A reuse system can help conserve the process liquid and control backwash losses.

Sample Applications

Our tubular filter is available in multiple tube configurations and are ideal for the following applications.

- Pulp and Paper Mills (White and River Water, Spray Nozzle Protection)

- Petrochemicals (Brine Caustic, Hydrochloric)

- Food and Beverage (Fruit Juices, Vegetable Oils, Syrups)

- Pharmaceutical and Cosmetics (Acetic Acid, Bath Oil, Citric Acid, Glycerin)

- Guard Filters (pre-filtration)

- Boiler Feed Water

- Condensate

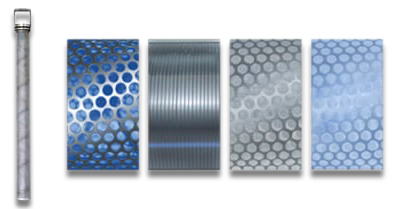

Filter Element Configurations

S. Howes Filtration offers four types of filter elements which allow for particle retention from 1 Micron (nominal) to 3/16 inch. Perforated stainless steel plate.

- Slotted wedgewire stainless steel screen

- Woven wire stainless steel screen over perforated plate

- Woven or non-woven cloth bag over perforated plate

Test Lab & Innovation Center

Your Material Product. Our Thermal Processing Equipment.

Make sure your new process equipment delivers your desired final material requirements.

Lab Testing

Leverage the CPEG Innovation Center and expertise in process engineering to test material product prior to the design or purchase of bulk solids and material handling equipment.

Testing With Rental Units

When material testing in the Innovation Center is not feasible, S. Howes provides rental equipment that can be shipped directly to your site for reliable testing of powder and bulk solids materials.