Power Sifter

Boost efficiency with S. Howes’ centrifugal power sifters.

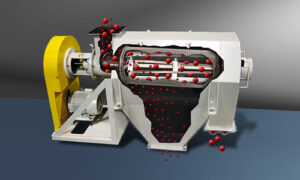

High capacity Centrifugal Power Sifters separate clumps from desired material by means of rotating paddles which push material through a sieve screen. Numerous screen cloths, mesh and wedge wire screens (for more abrasive materials) are available to achieve capacities as high as 100,000 lbs. per hour. Sifter throughput capacity is dependent on product density, characteristics, and screen size.

Our Power Sifters feature a heavy-duty construction build and low horsepower requirements for reliable and efficient processing of a variety of bulk solids products. Five models are available in mild steel or stainless steel for sanitary applications along with custom power sifter options.

Sift and screen with an S. Howes Centrifugal Power Sifter.

Features & Benefits

- Versatile design processes virtually any dry product or slurry.

- Low RPM and horsepower requirements with minimal vibration and few moving parts provides efficient and reliable sifting.

- Adjustable paddle design for various process requirements.

- Stainless steel construction for sanitary applications or mild steel for more robust or abrasive applications.

- Quick screen change design for product changeovers and cleaning.

- Easy to clean and maintain.

Sifting With Power

Our sifting and screening machines can process most dry products and slurries. Sifter throughput capacity is dependent on product density, characteristics, and screen size. Contact our sales department for more information or to schedule a product test.

Sample Applications

Our air finisher products perform reliable and efficient cleaning and screening of materials in a wide variety of industries.

- Beans

- Candy

- Corn

- Feed

- Grain

- Oats

- Pellets

- Plastics

- Rice Hulls

- Seeds

- Spinach

- Wood Chips

Downloads

Options & Accessories

Screens

- Screen sizes from 5000 Microns (4.3 Mesh) to 150 Microns (100 Mesh)

- Metal, Polyester or Nylon Mesh

- Durable Wedgewire for abrasive materials

Access

- Viewing Windows

- Cleanout Doors

- Access Ports

- Sanitary Clamp Fittings

Drives

- Variable Speed Drives

- TEFC Motor

- Explosion Proof Motor

- Hostile Environment Motor

Test Lab & Innovation Center

Your Material Product. Our Thermal Processing Equipment.

Make sure your new process equipment delivers your desired final material requirements.

Lab Testing

Leverage the CPEG Innovation Center and expertise in process engineering to test material product prior to the design or purchase of bulk solids and material handling equipment.

Testing With Rental Units

When material testing in the Innovation Center is not feasible, S. Howes provides rental equipment that can be shipped directly to your site for reliable testing of powder and bulk solids materials.