Filter Systems

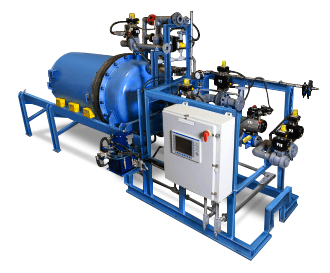

Save on installation costs with our factory piped, skid mounted & programmed industrial filter systems.

In addition to designing and manufacturing ASME Code Registered and CRN Registered Filters, Howes Filtration designs and builds complete filtration systems, from concept, to start-up & training. Systems typically are skid mounted, and factory piped, wired, and programmed. This process minimizes installation time and disruption of production. Designs integrate with pre-existing tanks, piping, instrumentation and controls. Control panels are typically provided with HMI for operator friendly interface and can communicate with all DCS systems for the food, beverage, chemical, refining, mining, pharmaceutical, sanitary and waste treatment industries.

For any processes working with solids in a liquid we can offer a separation solution. We offer dry cake and wet cake discharge filters with both vertical and horizontal tank and leaf orientations. We also offer custom nutsches, candle and basket filters.

The expert engineers at S. Howes have decades of experience designing complete process lines. From separators and screeners, to lump breakers, mixing equipment, and conveying lines, trust the experts to deliver your process system.

Let the filtration experts design your next industrial filter system.

Single Tube, Dual Tube, Multiple Tube & Complete Industrial Filter Systems

Test Lab & Innovation Center

Your Material Product. Our Thermal Processing Equipment.

Make sure your new process equipment delivers your desired final material requirements.

Lab Testing

Leverage the CPEG Innovation Center and expertise in process engineering to test material product prior to the design or purchase of bulk solids and material handling equipment.

Testing With Rental Units

When material testing in the Innovation Center is not feasible, S. Howes provides rental equipment that can be shipped directly to your site for reliable testing of powder and bulk solids materials.