CONTACT A SALES REPRESENTATIVE TODAY Request A Quote

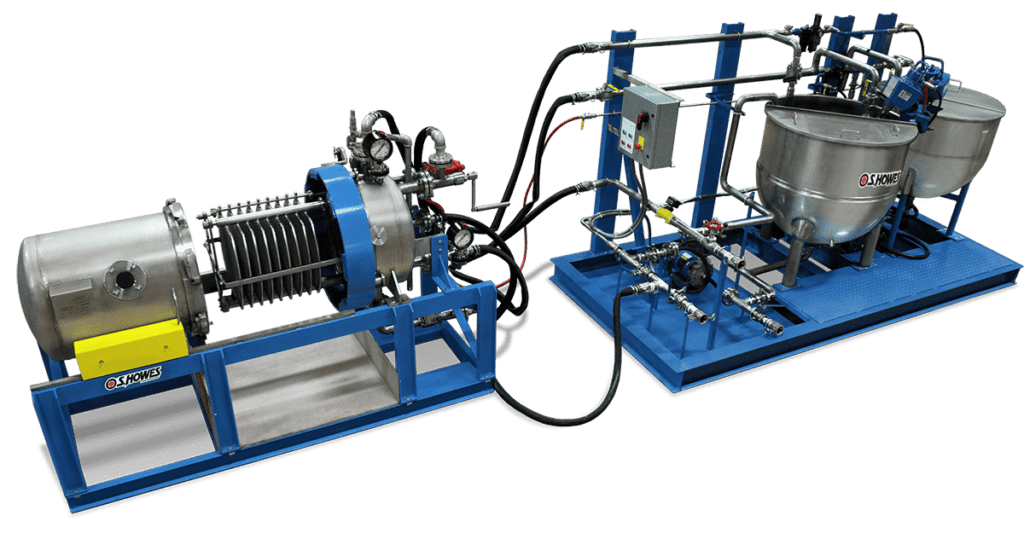

In addition to designing and manufacturing ASME Code Registered and CRN Registered Filters, Howes Filtration designs and builds complete filtration systems, from concept, to start-up & training. Systems typically are skid mounted, and factory piped, wired, and programmed. This process minimizes installation time and disruption of production. Designs integrate with pre-existing tanks, piping, instrumentation and controls. Control panels are typically provided with HMI for operator friendly interface and can communicate with all DCS systems for the food, beverage, chemical, refining, mining, pharmaceutical, sanitary and waste treatment industries. For any processes working with solids in a liquid we can offer a separation solution. We offer dry cake and wet cake discharge filters with both vertical and horizontal tank and leaf orientations. We also offer custom nutsches, candle and basket filters.

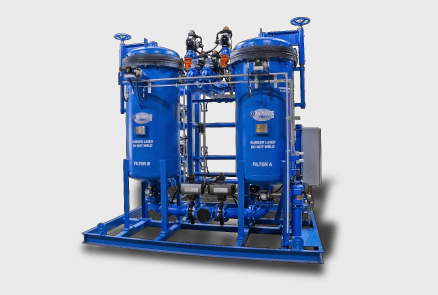

DUAL VERTICAL FILTRATION SYSTEM

S. Howes dual vertical filter station is recovering rare earth oxides at one of the world’s most technologically advanced, rare earth element production facilities. To meet material specifications, these units are rubber lined and have titanium wetted internals. The piping and valves are Teflon lined, and each vessel has 251 sq. ft. of filtration area. This system operates one on stream, and one in standby, at 60 + GPM. Each filter is equipped with an oscillating spray header to wash off the cake between cycles.

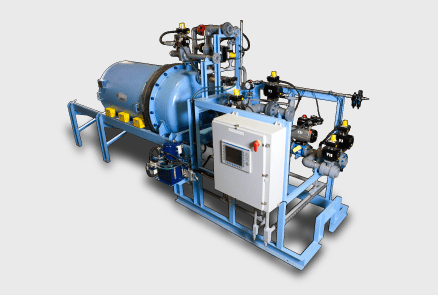

CHLORINE WET CAKE DISCHARGE

This filter station was pre-piped, pre-wired and pre-programmed at the factory for ease of installation. The filter has 311 sq. ft. of filtration area, is rubber lined and has titanium wetted Internals. The piping and valves are CPVC. The unit is filtering Sodium Hypochlorite for a large chemical manufacturer.