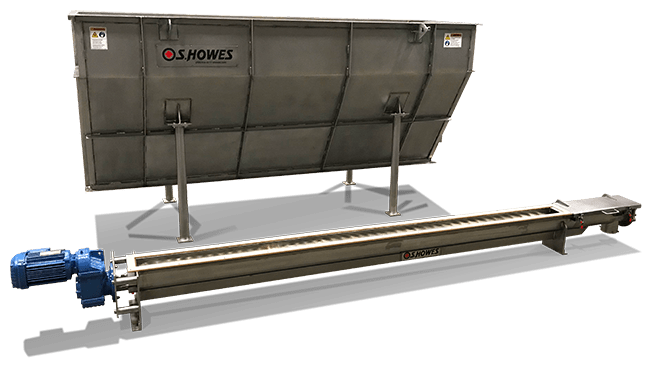

Conveying Systems

Streamlining processes & boosting productivity with custom conveying systems engineered by S. Howes.

Conveying systems are custom-engineered by S. Howes to meet difficult process requirements. Our custom conveying systems offer a range of benefits across various industries. Whether it’s automating food processes such as unloading systems with sanitary screw conveyors and feeders with a quick cleanout design, incorporating thermal jackets into conveying systems to cool high-temperature chemicals or designing portable or inclinable split-tube conveyors that provide adaptability, S. Howes has you covered.

When multistep processes require innovative solutions, our mechanical conveying experts work to understand your unique challenges. Material and process steps can be validated in our lab to facilitate the delivery of an efficient, reliable solution that streamlines processes and boosts productivity.

Do more in your process line with an S. Howes Conveying System.

Custom Conveying

& Material Handling Systems

Test Lab & Innovation Center

Your Material Product. Our Thermal Processing Equipment.

Make sure your new process equipment delivers your desired final material requirements.

Lab Testing

Leverage the CPEG Innovation Center and expertise in process engineering to test material product prior to the design or purchase of bulk solids and material handling equipment.

Testing With Rental Units

When material testing in the Innovation Center is not feasible, S. Howes provides rental equipment that can be shipped directly to your site for reliable testing of powder and bulk solids materials.