Wood Chip System for Forest Products Company

A forest products company contacted S. Howes to design a system which would ...

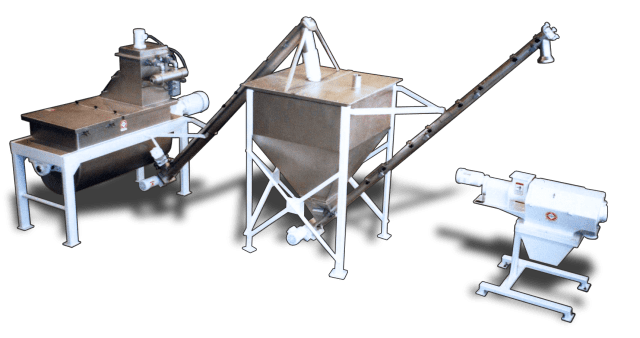

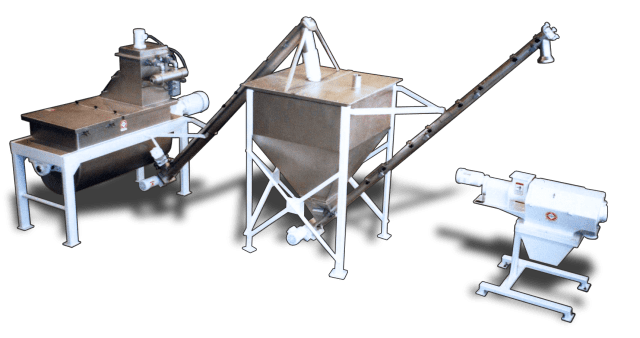

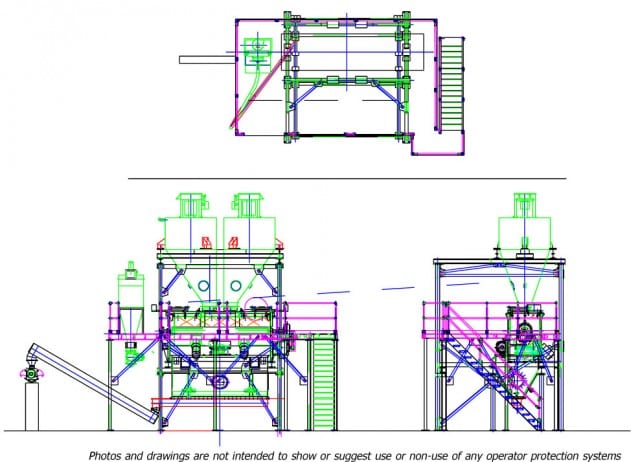

Self Unloading Bin and Conveyor System

An adhesive mixing company contacted S. Howes to build a self unloading bin ...

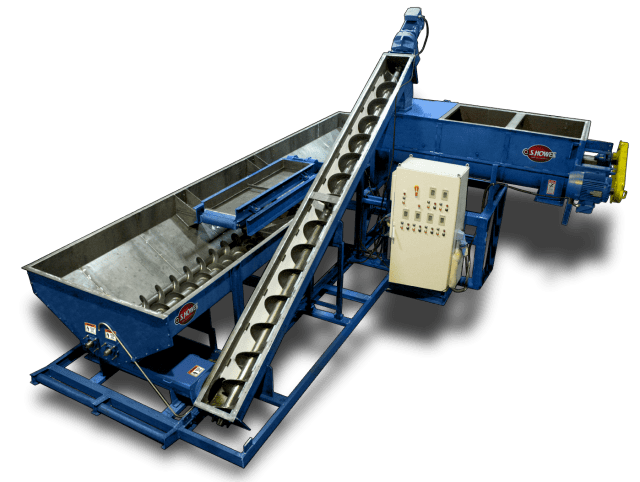

Rubber Mixing & Feeding System

A processor of recycled rubber contacted S. Howes to see if it could build ...

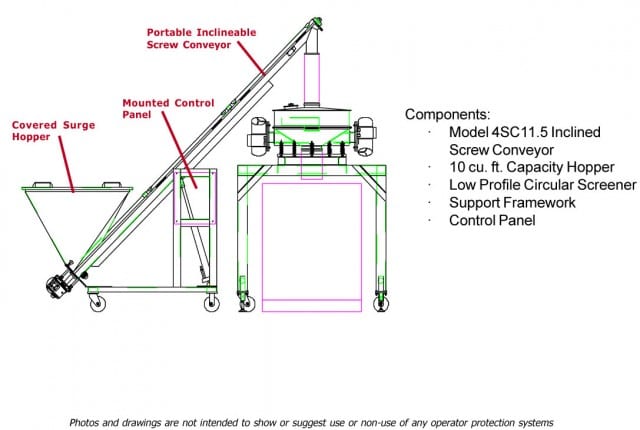

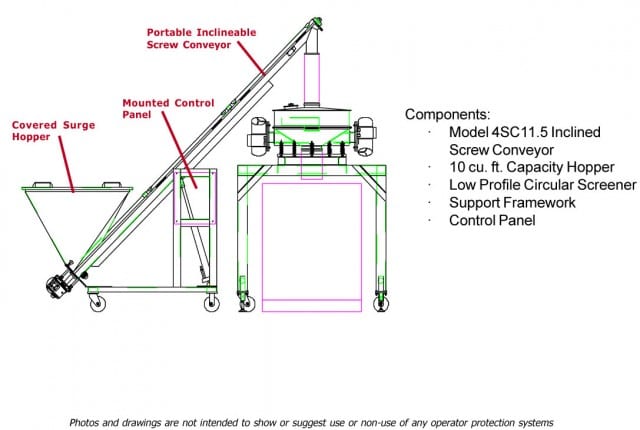

PVC Loading and Sifting System

A company contacted S. Howes to design a loading and sifting system to repl ...

Pigments Dryer Feeding System

A manufactuer of pigments was having difficulty achieving a consistent feed ...

Pancake Mixing System

S. Howes, Inc. was approached by a food processor to design a system to aut ...

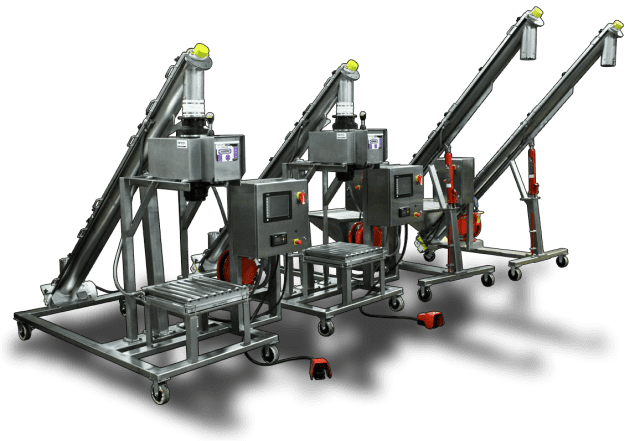

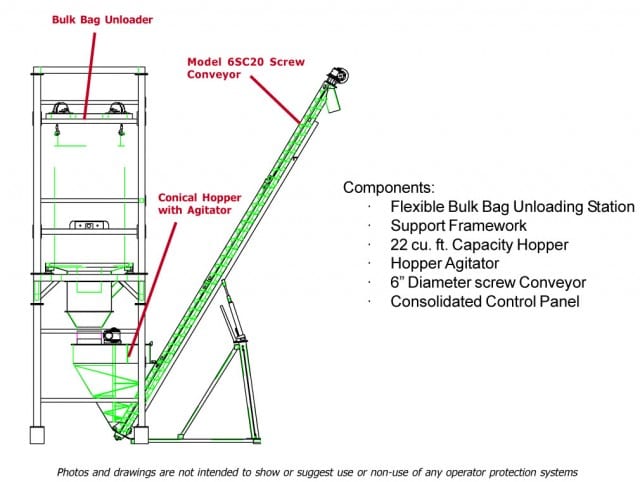

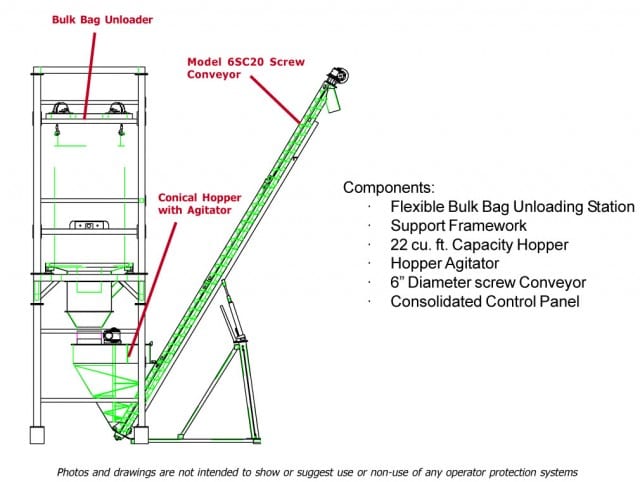

Food Ingredient Unloading & Conveying System

A food manufacturer was expanding its operations and contacted S. Howes to ...

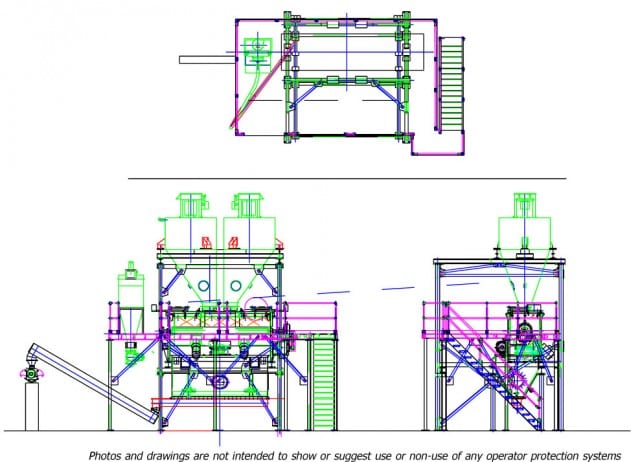

Flour Pre-Mixing & Bagging System

S. Howes, Inc. was approached by a food processor that needed a new system ...

Flour Mixing & Bagging System

S. Howes was approached by a bakery products manufacturer to assist in the ...

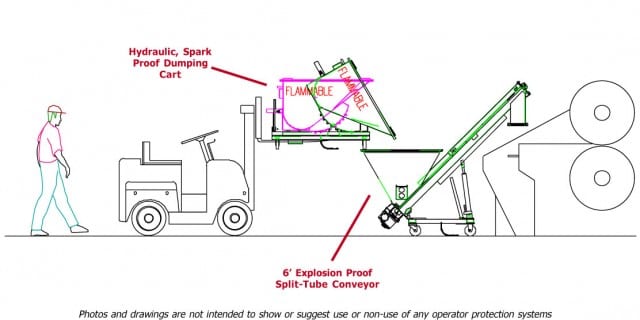

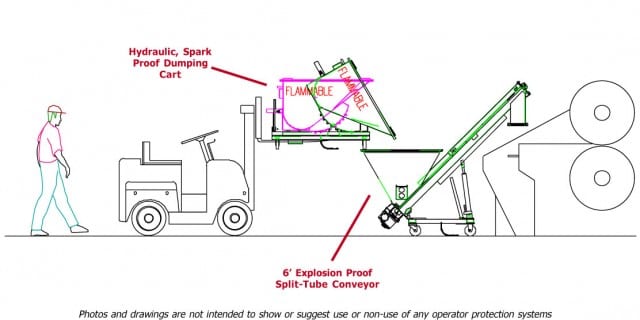

Feeding System for Flammable Materials

S. Howes was approached by a rubber sheet manufacturer to help reduce worke ...

Cooling Conveyor System for Battery Manufacturer

S. Howes was approached by a battery manufacturer that needed to replace a ...

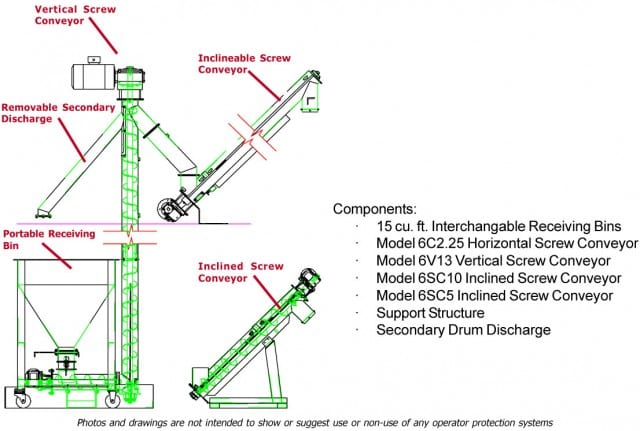

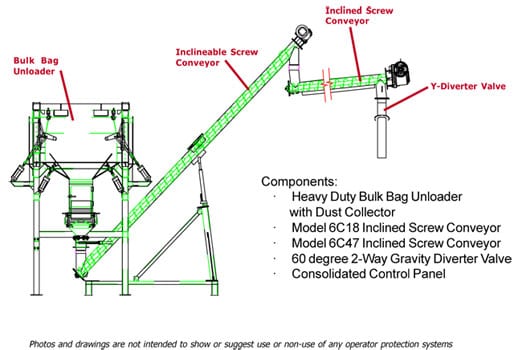

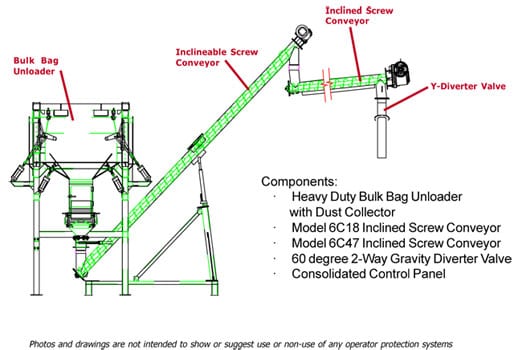

Chemical Power Loading and Conveying System

A company looking to expand its facility contacted S. Howes to design an un ...

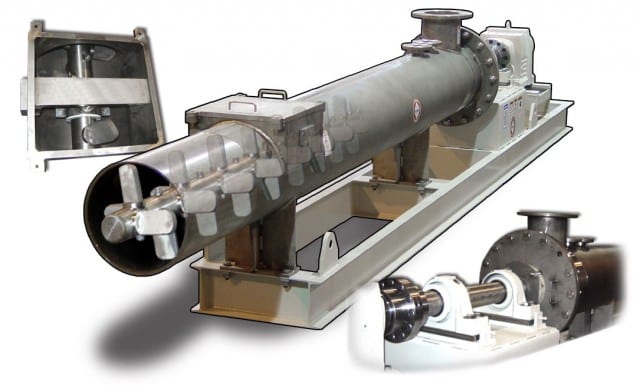

Frac Sand Continuous Mixer

The S. Howes Continuous Mixer (or Pug Mill) has been used to mix a variety ...

Conveyor with Sluggish Product

A customer came to S. Howes to fix a problem they were having conveying ...

Self Unloading Bin and Conveyor System

An adhesive mixing company contacted S. Howes to build a self unloading bin ...

Flour Pre-Mixing & Bagging System

S. Howes, Inc. was approached by a food processor that needed a new system ...

Flour Mixing & Bagging System

S. Howes was approached by a bakery products manufacturer to assist in the ...

Self Unloading Bin and Conveyor System

An adhesive mixing company contacted S. Howes to build a self unloading bin ...

Food Ingredient Unloading & Conveying System

A food manufacturer was expanding its operations and contacted S. Howes to ...

Cooling Conveyor System for Battery Manufacturer

S. Howes was approached by a battery manufacturer that needed to replace a ...

Chemical Power Loading and Conveying System

A company looking to expand its facility contacted S. Howes to design an un ...

Rubber Mixing & Feeding System

A processor of recycled rubber contacted S. Howes to see if it could build ...

Pigments Dryer Feeding System

A manufactuer of pigments was having difficulty achieving a consistent feed ...

Feeding System for Flammable Materials

S. Howes was approached by a rubber sheet manufacturer to help reduce worke ...

Wood Chip System for Forest Products Company

A forest products company contacted S. Howes to design a system which would ...

PVC Loading and Sifting System

A company contacted S. Howes to design a loading and sifting system to repl ...

Rubber Mixing & Feeding System

A processor of recycled rubber contacted S. Howes to see if it could build ...

Pancake Mixing System

S. Howes, Inc. was approached by a food processor to design a system to aut ...

Flour Pre-Mixing & Bagging System

S. Howes, Inc. was approached by a food processor that needed a new system ...

Flour Mixing & Bagging System

S. Howes was approached by a bakery products manufacturer to assist in the ...

Frac Sand Continuous Mixer

The S. Howes Continuous Mixer (or Pug Mill) has been used to mix a variety ...

Self Unloading Bin and Conveyor System

An adhesive mixing company contacted S. Howes to build a self unloading bin ...

Wood Chip System for Forest Products Company

A forest products company contacted S. Howes to design a system which would ...

Rubber Mixing & Feeding System

A processor of recycled rubber contacted S. Howes to see if it could build ...