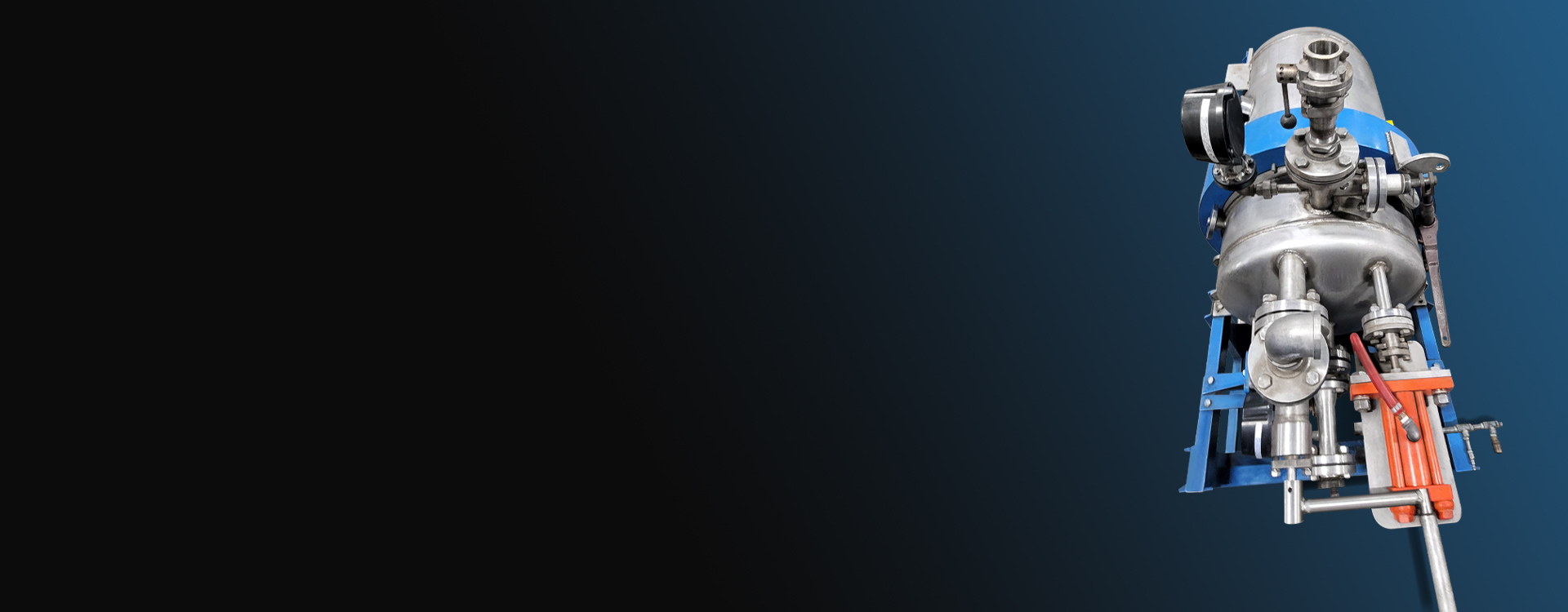

Improve Your Material Processing with Pressure Leaf Filter Solutions

The efficiency and precision of your filtration system can make or break your industrial processing. Whether you filter raw materials for biofuels, chemicals, food processing, or pharmaceuticals, you need quality equipment to get quality results. S. Howes’ Pressure Leaf Filter solutions increase the efficiency and quality of your material filtration.

Why Choose Pressure Leaf Filters?

Pressure leaf filters have become indispensable for processes requiring high flow rates and fine filtration. These filters separate solids from liquids, providing pure discharges for many industries.

Key Benefits of Pressure Leaf Filters:

Pressure leaf filters offer several advantages.

- High Efficiency: Capable of handling large volumes.

- Versatility: Suitable for a range of industries.

- Longevity: Built to last with robust materials.

- Precision: Achieves fine filtration down to 1/10 micron.

Pressure leaf filters provide many benefits, whether managing a high-volume production or a specialized project.

Wet Cake vs. Dry Cake: Tailored Solutions

We offer two primary types of pressure leaf filters—Wet Cake and Dry Cake. Each addresses specific challenges in material processing.

Wet Cake Pressure Leaf Filter

The Wet Cake Pressure Leaf Filter produces a “wet cake” during filtration. It is equipped with different leaf configurations and uses either an oscillating or hydrojet sluice mechanism for discharging the filtrate. Notable features include:

- Efficient Sluicing: Ensures clean discharge of wet cake.

- Multiple Configurations: Customizable to meet specific needs.

- Durability: Built with high-quality materials for longevity.

Wet Cake Pressure Leaf Filters are ideal for applications where moisture must be maintained. They excel in industries like biofuels and wastewater treatment.

Dry Cake Pressure Leaf Filter

The Dry Cake Pressure Leaf Filter is the go-to solution for processes requiring a “dry cake” or where sluicing isn’t feasible. It provides multiple leaf configurations with a large filtration area and a solids holding tank.

- Large Filtration Area: Maximizes efficiency.

- Solids Holding Tank: Keeps operations smooth.

- Robust Construction: Designed to withstand rigorous use.

Dry Cake Pressure Leaf Filters are perfect for chemical processing, petrochemicals, and other industries that require a dry discharge.

Applications Across Industries

Here’s a closer look at several industries benefiting from these advanced filtration systems:

Biofuels

Maintaining purity is paramount in the biofuels industry. S. Howes’ pressure leaf filters efficiently remove impurities, producing higher-quality biofuel products.

Pharmaceuticals

Pharmaceutical manufacturing demands precision and sterility. These leaf filters’ fine filtration capabilities make them ideal for ensuring product safety and efficacy.

Food and Pet Food Processing

Food safety regulations require stringent filtration processes. S. Howes’ solutions help achieve high clarity and purity levels, making them indispensable in food processing operations.

Chemicals and Plastics

Chemicals require precise separation techniques to ensure product quality. The robust design of S. Howes’ filters makes them suitable for handling aggressive chemical environments.

Advanced Features for Superior Performance

What sets S. Howes apart is their commitment to quality and innovation. Their pressure leaf filters come packed with features designed to enhance performance:

- Automated or Manual Hydraulic Shell Retraction: Offers flexibility depending on operational needs.

- Material Options: Built from a range of materials, including mild steel, stainless steel, and specialized exotic alloys to meet specific needs.

- High Polish Applications: Achieves 1/10 micron solids separation necessary for critical processes.

- Diatomaceous Earth Filter Aid: Enhances rate and clarity through pre-coat and body feed mechanisms.

These features ensure that each filter exceeds industry standards, providing reliable performance every time.

Contact Us for Customized Solutions

Ready to elevate your material processing with state-of-the-art filtration systems? Discover how S. Howes can provide customized solutions tailored to your specific needs.

Explore our Pressure Leaf Filter options and see how they can benefit your industry. For personalized assistance and inquiries, don’t hesitate to Contact Us today!