For many, recycling is seen as a noble pursuit that conserves natural resources, decreases energy use, mitigates climate change, and reduces pollution. Yet, the waste processing equipment used for advanced recycling operations has a more practical purpose. These days, it’s often more economically viable to recycle than to produce materials from their raw constituents.

Waste Processing Equipment for Modern Recycling Operations

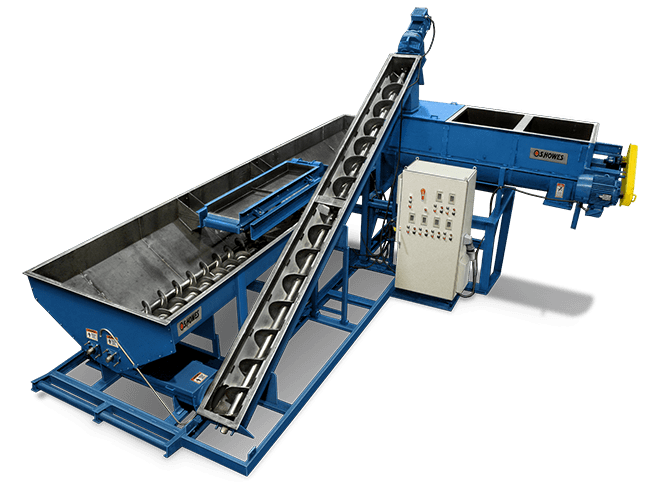

The recycling sector relies on robust machinery built to handle large amounts of reclaimable waste. Processing machines are designed and placed within systems to perform the various tasks involved in modern recycling operations as efficiently as possible.

For recycling waste, processing equipment is used for:

- Initial mechanical reduction of waste into smaller sizes and more uniform shapes.

- Material conveyed for further waste processing to machines that mix and separate.

- Sorting and separating materials by various means, such as density and magnetism.

- Removing improperly sized waste, with processing equipment screening materials before transporting them to the next stage.

- Breaking down base materials that are then often combined with additives to enable reuse of waste with processing equipment like mixers.

- Mitigating pollution of air or water used in waste processing, with machines featuring filtration devices that comply with regulatory requirements for reducing pollution.

Depending on the type of waste, processing equipment will perform various functions.

Reconditioning Waste: Processing Machines for Recycling Operations

An almost unlimited array of waste processing equipment is used for different applications throughout a recycling plant.

Size Reduction Equipment

Size reduction machinery that breaks down material into more manageable parts is normally the first step in waste processing. Equipment that crushes, grinds and shreds glass, metals and plastics makes separation and sorting in later stages much less difficult.

Screw Conveyors

Transporting recyclable material constantly and controlling between stages is a key aspect of waste processing—machines for conveying material move crushed and shredded material toward screening and separation areas. Requiring relatively little maintenance, screw conveyors can efficiently move both lightweight materials like plastics and heavier stuff like scrap metal.

Industrial Mixers

Regardless of the type of waste, processing equipment is often needed to mix recyclable materials. Industrial mixers can be used to recycle various substances. For example, organic matter for compost production is blended to ensure moisture is evenly distributed. This idea can be used for inorganic materials like asphalt or concrete, combined with bonding agents during recycling processes.

Screeners & Separators

Screening and separation equipment are important elements of any waste processing system. Machines that screen and separate recyclables help remove contaminants from recyclable material. Screening equipment removes oversized particles within a stream of waste. Processing equipment is also used to separate useful materials from less readily recyclable ones. Some separators use magnets to draw out ferrous metals from waste streams, while others use air classification to separate heavier materials like glass from lighter ones like plastics.

Filtering Equipment

Like screeners and separators, filtering systems help remove impurities and pollution from recycling operations, reducing airborne particulates and dust during waste processing. Machines featuring bag, cartridge or HEPA filters are often used to purify water or solvents used in recycling, especially for recovering valuable elements from e-waste.

To learn more about our waste processing equipment, contact S. Howes today.