PVC Loading and Sifting System

The Process Challenge

A company contacted S. Howes to design a loading and sifting system to replace its manual system. The material to be loaded and sifted by the system was powdered PVC resin, which presented complex flow challenges because it bridged quickly.

The Solution

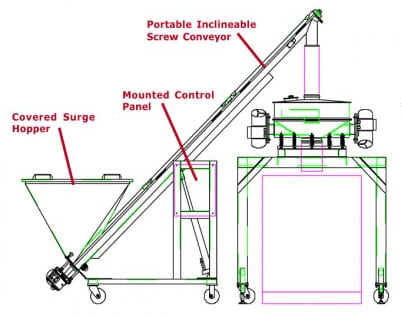

Keeping this in mind, S. Howes designed a system comprised of a covered surge hopper that fed a portable, inclinable screw conveyor and deposited the material into a low-profile circular screener, where it was sifted and discharged into bins for further processing. The system featured one of S. Howes’ unique split tube conveyors, which gave the company convenient access to the material and made the system easy to clean.

Components

- Model 4SC11.5 Inclined

- Screw Conveyor

- 10 cu. ft. capacity Hopper

- Low-profile Circular Screener

- Support Framework

- Control Panel

Photos and drawings are not intended to show or suggest use or non-use of any operator protection systems.

The Result

The company ended up with a system that successfully processed the PVC resin. It eliminated flow issues, was much easier to clean and could be easily controlled by the operator.