6SC10 Split Tube Conveyors

Standard Design Features

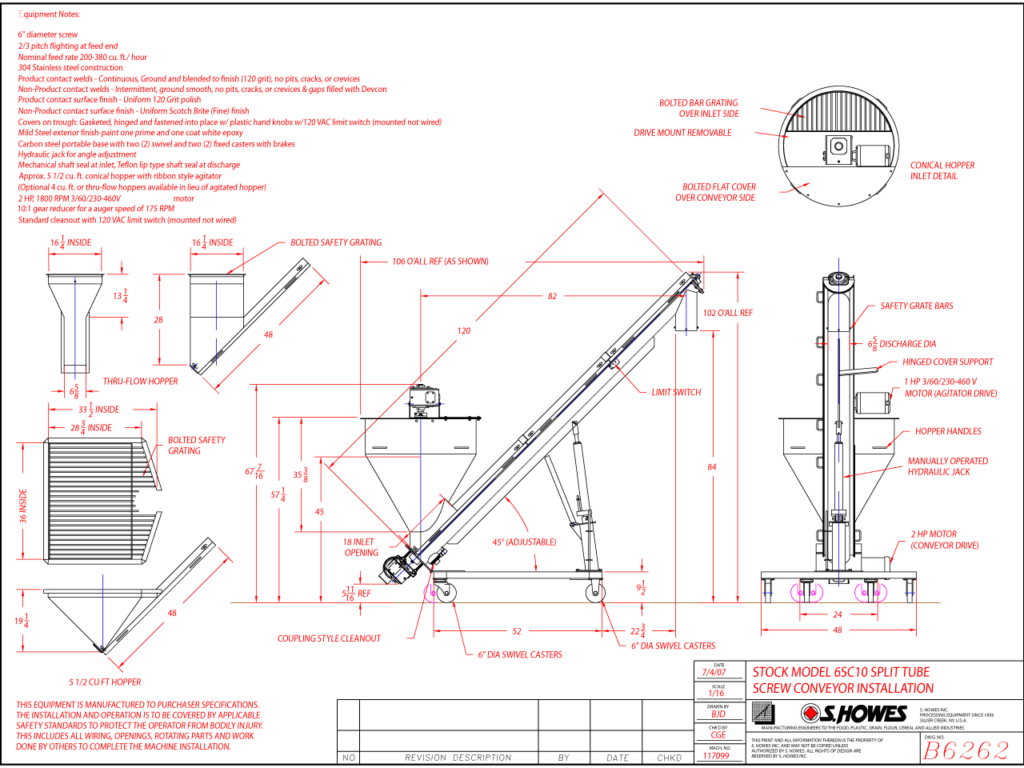

- 6″ diameter screw x 10′ long with 2/3 pitch inlet flighting, balance full pitch flighting

- 2-1/4 ft3 hopper with bolted safety grating

- 6″ standard pipe stub discharge

- 2 HP, 1800 RPM 3/60/230-460V TEFC (4:1) Inverter duty motor

- 10:1 gear reducer for final auger speed of approx. 175 RPM

- Standard cleanout with 120 VAC limit switch (mounted not wired)

- Controls, wiring and installation by customer

Construction Details

- 304 Stainless steel construction in product contact areas

- Interior surfaces uniform 80 grit finish

- Exterior surfaces uniform Scotch-Brite finish

- Continuous weld on both sides of flighting

- Welds in contact with product continuous and ground to 80 grit finish

- Welds not in contact with product intermittent and ground smooth, gaps filled with Devcon

- Rotating mechanical shaft seal on the drive and single lip seal on discharge end

- Covers on trough are gasketed, hinged and fastened into place with plastic hand knobs, with 120 VAC limit switch (mounted not wired)

- Exterior mild steel components (motor, bearings, etc.) to be one coat primer and one coat white epoxy

- Mild steel portable base with two (2) rigid and two (2) swivel casters with brakes and hydraulic jack for angle adjustment

To rent a stock item call 716.934.2611 or fill out and submit the form below.

Chemicals & Plastics

S. Howes designs and builds robust equipment for chemical and plastics plants. Most of our products are engineered-to-order and designed for your specific application. From caustic and abrasive to friable materials, our experienced staff will share their knowledge of chemical plant equipment and plastics processing to design your custom equipment solution. We have in-depth knowledge of applications with sensitive temperature and pressure requirements and can design customized processing solutions to meet your needs. In addition, our test lab is available to assist customers in selecting the right process equipment.