Shaker

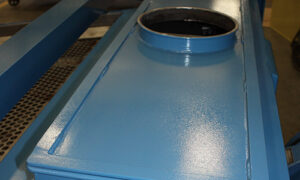

Superior screening is a snap away with Snappy Shakers.

Snappy Shakers are used for high-intensity screening, cleaning and/or sifting. Our Shaker screening machine is simple to install and easy to maintain. It features a robust design that provides long-lasting durability for many years. They provide superior screening capabilities for processing food ingredients, animal feed, pellets, minerals, and more.

Ten models are available with single, double, or triple deck configurations. Screening capacities range up to 50 tons per hour. The S. Howes Snappy Shakers are available in open, covered, or enclosed models for use outdoors or in dust-free environments. Triple deck models are available for additional separations for maximum efficiency.

Let our engineers design a Snappy Shaker for your industrial screening needs.

Features & Benefits

- High-quality, heavy-duty construction provides years of reliable processing.

- Low maintenance and low horsepower for economical operation.

- Constant ball agitation aids particle stratification and prevents screen blinding for more efficient cleaning, even with materials that clog easily.

- Barbeau oscillating, eccentric-less drive provides vigorous, smooth screen action that maintains production efficiency.

- Quick remove screen design for simple and rapid changeovers.

- Standard carbon steel construction with stainless steel options for sanitary or corrosive applications.

- Split-stream styles allow products to pass over the top and bottom deck simultaneously for double the scalping capacity.

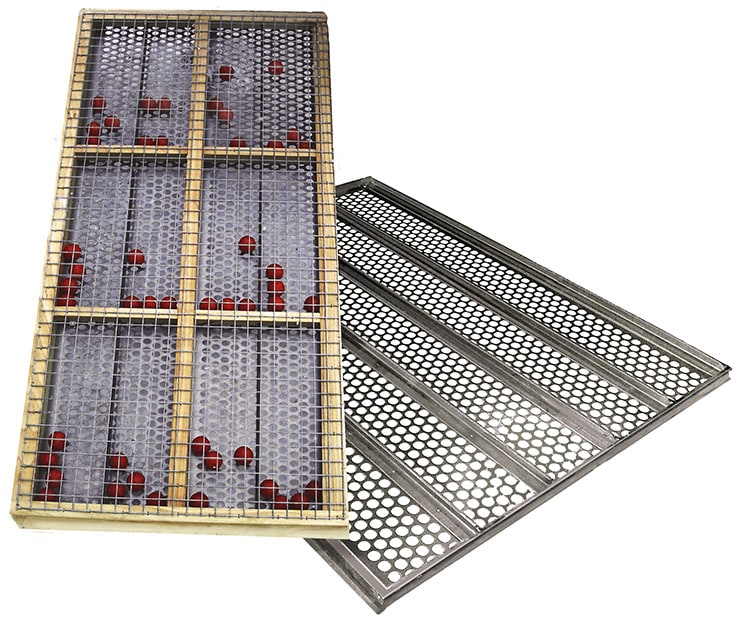

Ball Screening Deck

Our ball agitation design prmotes particle stratification, prevents screen blinding, and provides efficient cleaning.

Sample Applications

S. Howes authentic ball screens provide constant agitation to promote particle stratification for more efficient cleaning, even when used with materials that tend to clog easily.

- Cereal

- Spices

- Feed & Animal Feed

- Nuts

- Bark

- Beans

- Corn

- Wood Chips

- Oats

- Feed

- Grain

- Seed

- Rice Hulls

- Pellets

- Plastics

- Minerals

Downloads

Options & Accessories

- Custom ball screens

- Triple deck models

- Metal frame

- Removable dust covers

- Fully-enclosed (SL) model in all sizes for even more efficient dust confinement and outdoor use

- Custom perforations or wire mesh screens

- Split-stream styles

- Custom discharges

Test Lab & Innovation Center

Your Material Product. Our Thermal Processing Equipment.

Make sure your new process equipment delivers your desired final material requirements.

Lab Testing

Leverage the CPEG Innovation Center and expertise in process engineering to test material product prior to the design or purchase of bulk solids and material handling equipment.

Testing With Rental Units

When material testing in the Innovation Center is not feasible, S. Howes provides rental equipment that can be shipped directly to your site for reliable testing of powder and bulk solids materials.