CONTACT A SALES REPRESENTATIVE TODAY Request A Quote

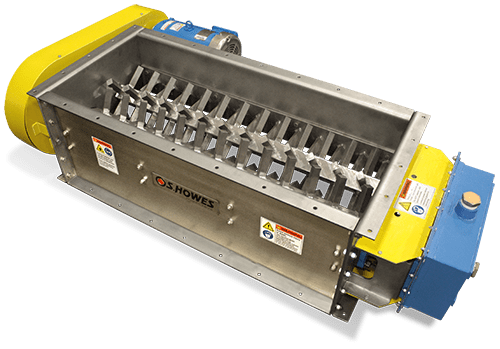

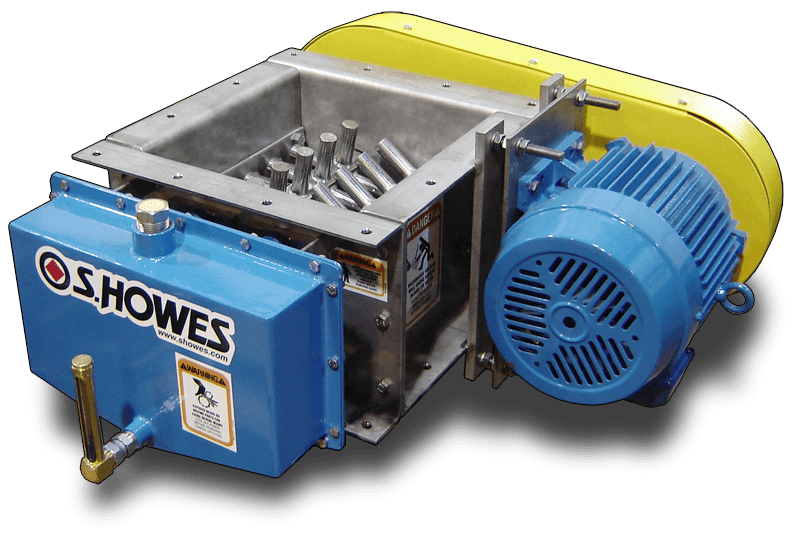

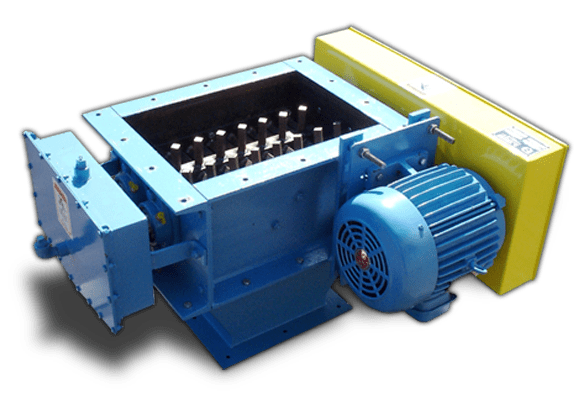

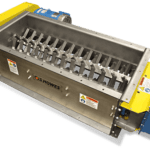

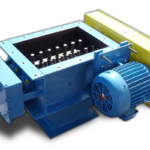

Lump breakers are designed to reduce softer and abrasive products such as filter cakes, foodstuffs, chemicals, fertilizers, and fly ash into sizes that can be further processed downstream. They can be placed in-line to reduce materials into manageable sizes for conveyors and/or other process equipment or as a stand-alone unit with customized support structures and appropriate safety measures included. All models are available in mild steel, stainless steel, or other alloys with various power transmission options to suit most industrial applications.

Depending on process requirements and capacity, five standard lump breaker machine models are available. Additional options include twin or single-shaft designs, portable bases, and inlet feed hoppers that can be adapted to suit individual process needs.

Complimentary services include factory and field pilot testing for equipment selection and performance optimization.

Testing & Rental Units Available Rental Equipment

Features

- Robust design for long-lasting durability and reliability

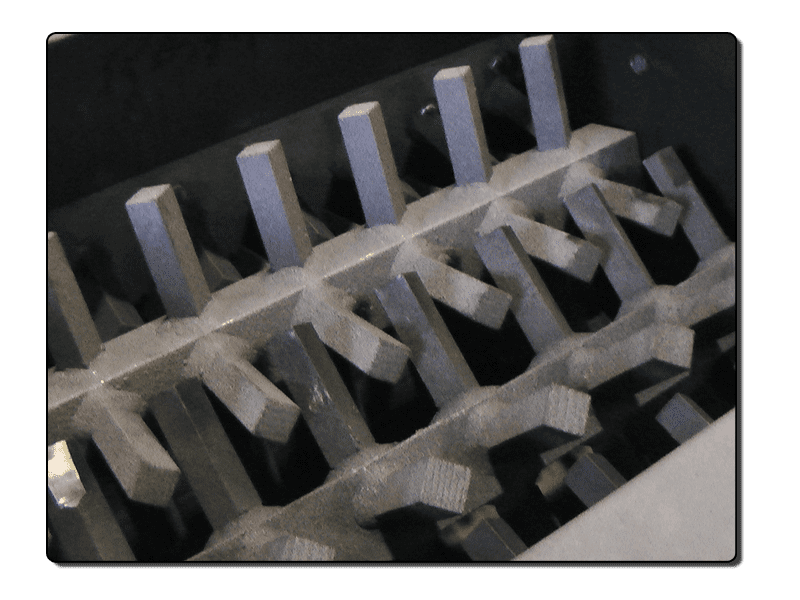

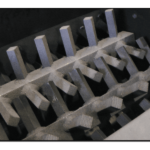

- Counter rotational drive with steel gears to transmit power between shafts

- Flanged inlets and outlets

- Abrasion-resistant pin options

- Twin shaft design with stationary and rotary pins

- Optional tungsten carbide coating on pin leading edges

- Optional dynamic balancing of the shafts

- Round pins can be used to reduce product damage

- Explosion-proof motor options

Sample Applications

- Filter Cake

- Food Products

- Frozen Foods

- Chemicals

- Fertilizer

- Salt

- Powders with Lumps

- Fly Ash & Cement