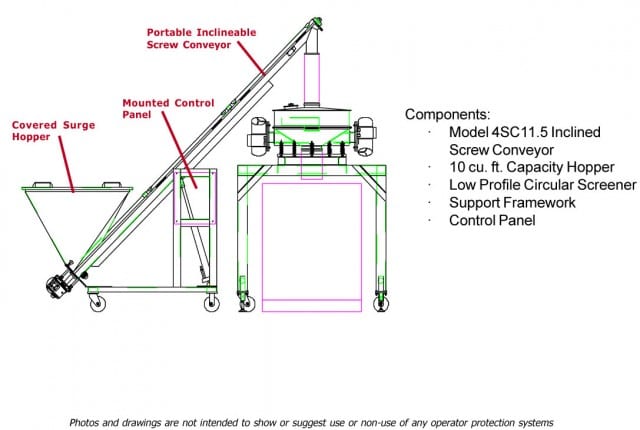

A company contacted S. Howes to design a loading and sifting system to replace its existing manual system. The material to be loaded and sifted by the system was powdered PVC resin which presented difficult flow challenges because it bridged easily. Keeping this in mind, S. Howes designed a system comprised of a covered surge hopper which fed a portable, inclinable screw conveyor and deposited the material into a low profile circular screener where it was sifted and discharged into bins for further processing. The system featured one of S. Howes’ unique split tube conveyors which gave the company convenient access to the material and made the system easy to clean.